What is a wire belt bucket elevator?

Monday April-28 2025 16:43:14

The wire belt bucket elevator uses its high-strength steel cord belt as a traction component to achieve vertical and efficient transportation of bulk materials. The material is continuously transported through a hopper fixed on the belt. It is suitable for powder, granular or small block materials with a particle size of less than 50mm and a screening mesh of 20 to 500 mesh. The lifting height can reach 5 to 120 meters, and the conveying capacity ranges from 15 to 800 cubic meters per hour.

Video of wire belt bucket elevator

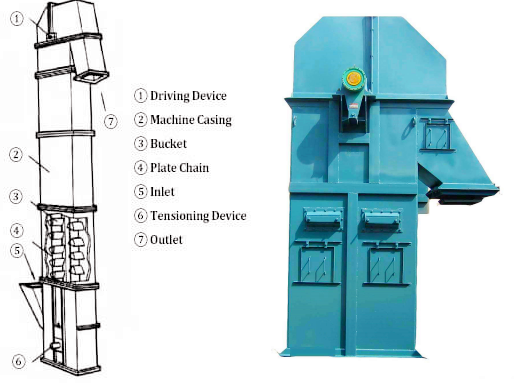

What is the structure of a wire belt bucket elevator?

The wire belt bucket elevator is a mechanical equipment used to continuously transport bulk materials vertically or at a large angle. Its core is a wire rope core conveyor belt (wire belt) plus a series of fixed hoppers, which carry the material from bottom to top.

①Wire tape: It is composed of multiple layers of high-strength steel wire rope as the skeleton, and the outer layer is covered with wear-resistant rubber. It has both flexibility and tensile strength, can withstand large loads and is not easy to deform.

②Hopper: Select according to material characteristics (such as particle size, humidity), suitable for screening powdery and granular materials (such as cement, ore, grain) with mesh size of 10-200.

③Drive device: Usually located at the top of the equipment, including motor, reducer and drive roller, providing power to drive the belt to circulate.

④Tensioning device: Located at the bottom, it prevents slipping or deviation by adjusting the tension of the belt to ensure operational stability.

⑤Casing: Closed structure to prevent dust from spilling and protect internal components, usually with inspection doors and observation windows.

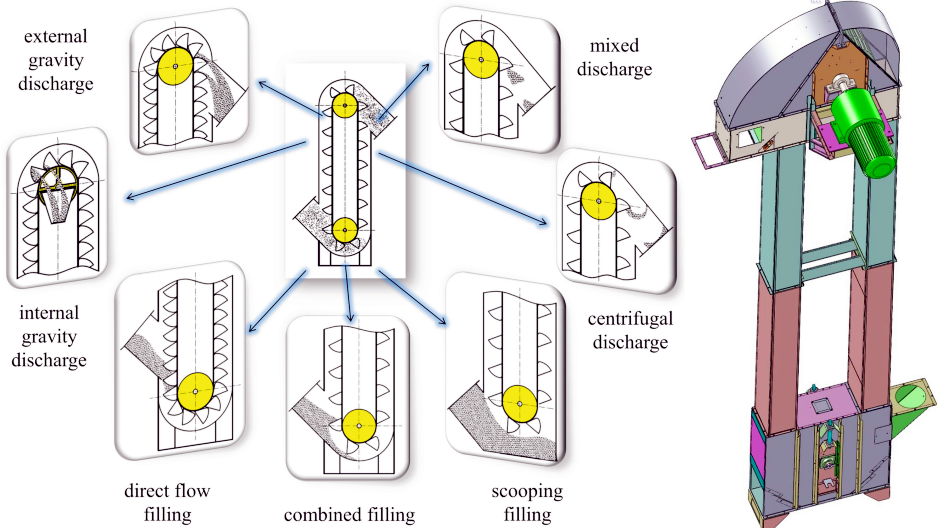

How does a wire belt bucket elevator work?

The elevator is a continuous conveying machine that uses a wire rope core belt as a traction component and is equipped with a series of buckets for vertically lifting bulk materials. The working principle of a wire belt bucket elevator is similar to that of other bucket elevators. The material enters the hopper from the feed port at the bottom, and the hopper moves upward with the steel wire belt. At the discharge port at the top, the material is discharged under the action of gravity or centrifugal force. Then, the empty hopper returns to the bottom with the belt for the next loading.

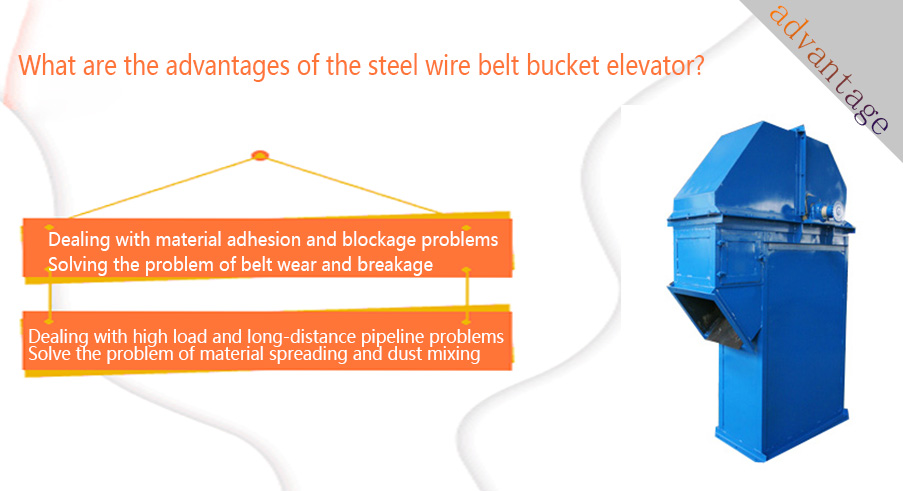

What are the advantages of the steel wire belt bucket elevator?

Dealing with material adhesion and blockage problems: The hopper design is optimized, and a smooth surface or anti-coating is used to reduce the unloading device. A vibration device or a cleaning mechanism is set at the discharge port to prevent siltation. For high humidity or sticky materials (such as wet coal), a forced unloading device can be equipped to ensure that there is no more unloading.

Solving the problem of belt wear and breakage: The steel wire belt adopts a high-strength steel wire rope core and a wear-resistant rubber covering layer, with a tensile strength of nearly 2000-8000N/mm and excellent fatigue resistance. Equipped with a tensioning device to maintain the appropriate tension of the belt and reduce fatigue. A wear-resistant lining is added to the top surface of the stack to reduce tension.

Dealing with high load and long-distance pipeline problems: The high-strength design of the wire hoist supports a lifting height of more than 100 meters, and the pipeline capacity is close to 200 tons/hour. The drive adopts a device motor and a town device, equipped with an overload protection system to prevent overload damage, meet the needs of large-scale and long-distance pipelines, and operate reliably.

Solve the problem of material spreading and dust mixing: The casing has strong sealing, adopts an additional design, and is equipped with a dust removal interface to connect the dust removal equipment. The powder and shape of the hopper are accurately calculated and scattered during lifting or unloading. A guide plate is set at the feed inlet to ensure that the material enters the hopper evenly, reduce inventory losses, and improve the working environment.

Application scenarios of wire belt bucket elevator

Wire belt bucket elevator has been widely used in many industries due to its high strength, wear resistance, and smooth operation.

In the cement industry, it is mainly used to lift cement clinker, limestone, gypsum powder and other materials, especially suitable for conveying powdered and granular raw materials with high temperature, particle size less than 50mm, and screening mesh between 20 mesh and 200 mesh.

In the mining industry, wire belt bucket elevators are often used to lift ore and mineral powder, such as iron ore concentrate and copper ore powder. The lifting height is usually more than 50 meters, and the conveying volume is required to be large.

In the power industry, it is used to convey fly ash, coal fines and other dusty materials. The equipment design focuses on sealing and dust prevention to ensure environmental protection standards.

In the grain industry, it is used to vertically convey wheat, soybeans, corn and other grains. The bucket and belt materials are required to meet food safety standards to prevent pollution.

In the chemical industry, to lift various powder materials such as barium sulfate powder and calcium carbonate powder, the equipment is required to have strong corrosion resistance and be able to adapt to high-frequency start-up and operation conditions.

In summary, because the wire belt bucket elevator can adapt to complex environments such as high temperature, high dust, and large conveying volume, and has low maintenance, it has become the first choice for efficient and reliable conveying equipment in these industries, mainly concentrated in the field of vertical conveying of bulk materials that require large transportation volume and high lifting height. Its superior performance makes it play an important role in modern industrial production.