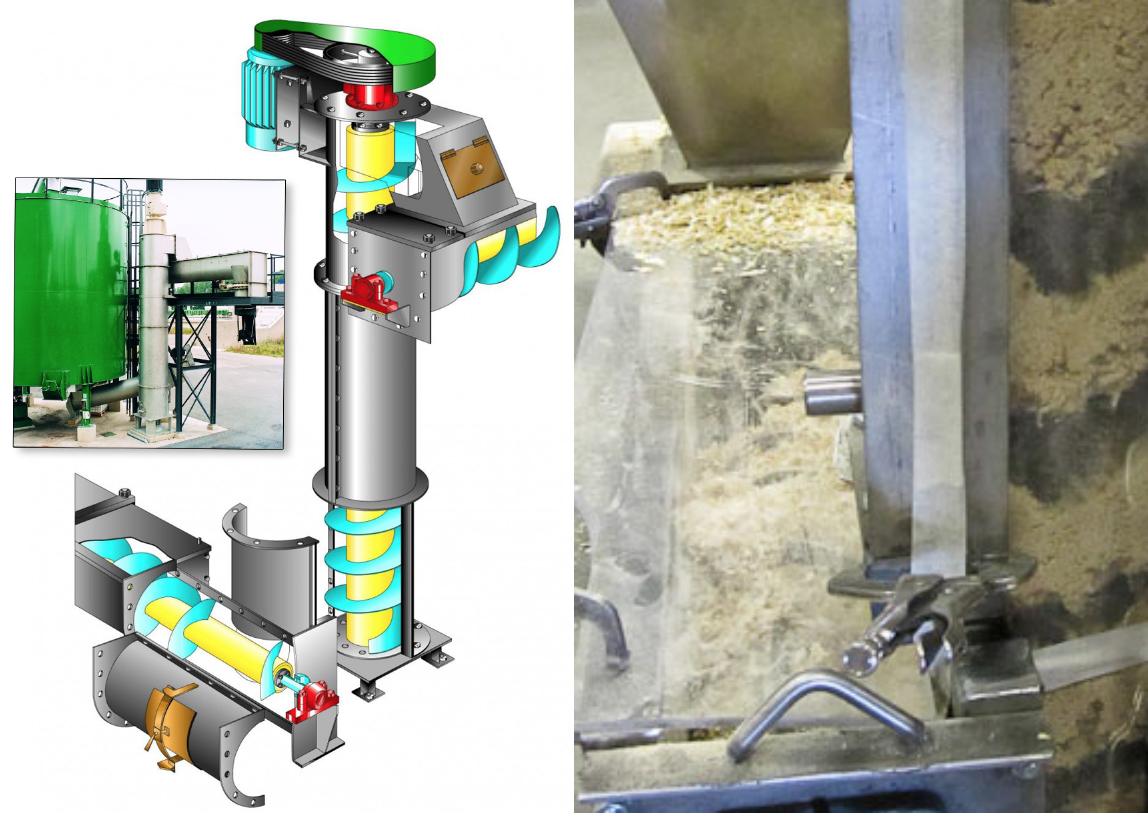

Wheat bran vertical screw conveyor

Tuesday June-03 2025 17:25:45

As a by-product of wheat processing, wheat bran has the characteristics of light weight (bulk density ≤1.3t/m³), dryness and good fluidity. The wheat bran vertical screw conveyor uses rotating spiral blades, centrifugal force, the material's own gravity and friction with the casing to convey the wheat bran upward in the vertical direction. This conveying method can achieve 90° vertical lifting. In addition, its conveying process is smooth and it is not easy to get stuck, which can ensure smooth and uniform conveying of wheat bran.

Applicable materials for wheat bran vertical screw conveyor

The wheat bran vertical screw conveyor is suitable for conveying powdery or granular materials with good fluidity, non-stickiness, and dryness, mainly powdery (such as wheat bran, flour, cement) and granular (such as grains, feed pellets, sand). The material particle size is moderate, without large agglomeration or fiber entanglement. Typical materials are as follows:

Wheat bran (main applicable material, by-product of flour processing); rice bran, bean skin powder, corn husk powder;

Bran powder, flour scraps; carrier components in premixes (such as puffed bran, plant fiber powder);

Crushed grass powder, rice husk powder; light mineral powder (such as bentonite, diatomaceous earth); light feed additive raw materials;

The material is required to be non-sticky and low in humidity to avoid the material adhering to the spiral blades or the inner wall of the casing due to moisture or stickiness, affecting the conveying efficiency or even clogging the equipment. For example, wheat bran itself is dry and loose, which is suitable for this equipment; but wet soil and high-viscosity slurry are not suitable.

What are the application scenarios of wheat bran vertical screw conveyor

Wheat bran vertical screw conveyor is widely used in grain processing and feed production industries, especially in wheat processing plants, feed mills and food processing enterprises. In wheat processing plants, it is used to lift wheat bran from a low place to storage warehouses or subsequent processing equipment to ensure the efficient operation of the production line. In the feed production process, the vertical screw conveyor can quickly convey ingredients such as wheat bran to the mixer to ensure the accuracy and consistency of the feed formula.

In flour mills, wheat bran is treated as a by-product, and the conveyor is responsible for efficiently transferring it to the packaging area for subsequent sales and use. In addition, the equipment can also be used in grain depots to transport wheat bran to different storage tanks or loading areas to optimize storage management.

Engineering Guide for Wheat Bran Vertical Screw Conveyor

① Material characteristics analysis:

Wheat bran has a low density and relatively good fluidity, but it is easily affected by air resistance during vertical transportation. The abrasiveness is usually low, and the requirements for the conveyor material can be appropriately considered economical. Consider the hygroscopicity of wheat bran to avoid blockage due to moisture absorption and agglomeration during transportation.

② Design selection:

Determine the required conveying capacity and the height of vertical conveying according to process requirements. Select the appropriate screw size according to material characteristics and conveying volume. For light materials, a larger pitch may be required to improve conveying efficiency. Reasonably control the screw speed to avoid the flying or falling of materials due to excessive speed, which affects the conveying efficiency. Reasonable design of the inlet and outlet can ensure smooth feeding and unobstructed discharge.

Wheat bran vertical screw conveyor manufacturer

As a manufacturer of wheat bran vertical screw conveyors, Dahan Machinery focuses on providing conveying solutions for industries that need to lift wheat bran vertically. Their wheat bran vertical screw conveyors usually take into account the light and fluffy characteristics of wheat bran, and may use more suitable pitches and speeds in design to ensure conveying efficiency and reduce the flying or retention of materials during transportation.

As a manufacturer, Dahan Machinery provides vertical screw conveyors of different specifications and materials to meet the conveying volume and requirements of different customers. It also provides customized services to design conveyor solutions suitable for their production processes according to the specific needs of different customers.

Whether in wheat processing, feed production or other related fields, Dahan Machinery's wheat bran vertical screw conveyor can provide customers with efficient and economical material conveying options, helping to improve production efficiency and automation level.