Z-type bucket elevator for bentonite transportation

Saturday April-26 2025 19:15:35

What is Z-type bucket elevator for bentonite transportation?

The Z-type bucket elevator for bentonite transportation is specially designed and manufactured for the characteristics of bentonite. It is an efficient vertical and horizontal transportation equipment. Bentonite has good water absorption, expansion, adhesion and cation exchange properties, and is often used in drilling mud, foundry sand, cat litter, decolorizer and other industries. According to different application requirements, bentonite usually needs to be screened to 60 mesh, 100 mesh, 200 mesh or even finer mesh. It can lift and transport bentonite from one location to another in a complex spatial environment. It is suitable for bentonite production enterprises of various sizes and industrial scenarios using bentonite.

Classification of Z-type bucket elevator for bentonite transportation

|

Classification |

Stainless steel Z-type bucket elevator |

Carbon steel Z-type bucket elevator |

|

Material |

304/316L stainless steel, corrosion-resistant, in line with food grade or chemical grade standards |

High-quality carbon steel, usually sprayed or galvanized on the surface, economical and durable |

|

Applicable bentonite characteristics |

High water absorption, viscosity, strong chemical stability, suitable for fine powder (80-325 mesh) or corrosive environment |

Moderate water absorption and expansion, suitable for general particles or powder (80-200 mesh), no strong corrosive environment |

|

Screening mesh adaptation |

80 mesh, 200 mesh, 325 mesh and other fine screening, with vibrating screen Conveying, ensuring uniform particles |

80 mesh and 200 mesh are mainly suitable for medium and coarse screening material transportation |

|

Corrosion resistance |

Excellent, acid and alkali resistant, suitable for the application of bentonite in chemical, pharmaceutical and environmental protection fields |

General, suitable for non-corrosive or low-corrosive environments |

|

Application scenarios |

fine chemicals, pharmaceuticals, food-grade cat litter production lines, environmental protection treatment equipment |

building materials (ceramics, sealing materials), drilling fluid ingredients, general industrial production lines |

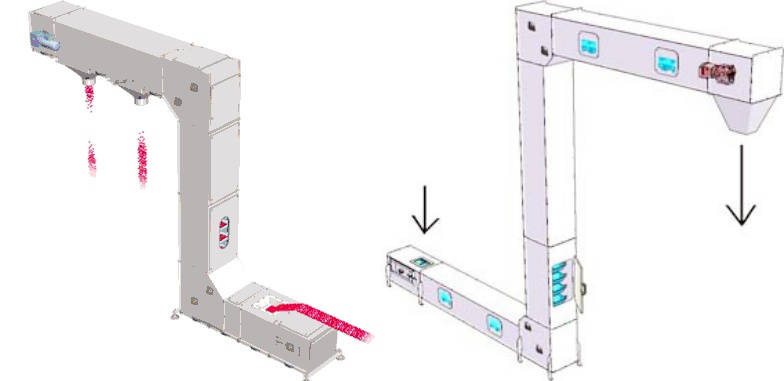

Working principle of Z-type bucket elevator for bentonite transportation

①Driven by a motor, the chain or belt is driven to operate, and the hopper installed on the chain or belt moves accordingly.

②At the bottom feed port , the hopper scoops up the bentonite, and as the chain or belt is lifted, the hopper lifts the bentonite to the specified height, and then unloads the bentonite to the target location through the unloading device.

③ The Z-shaped structural design enables the elevator to achieve a large height lift in a limited space, and can also meet the transportation needs of a certain distance in the horizontal direction.

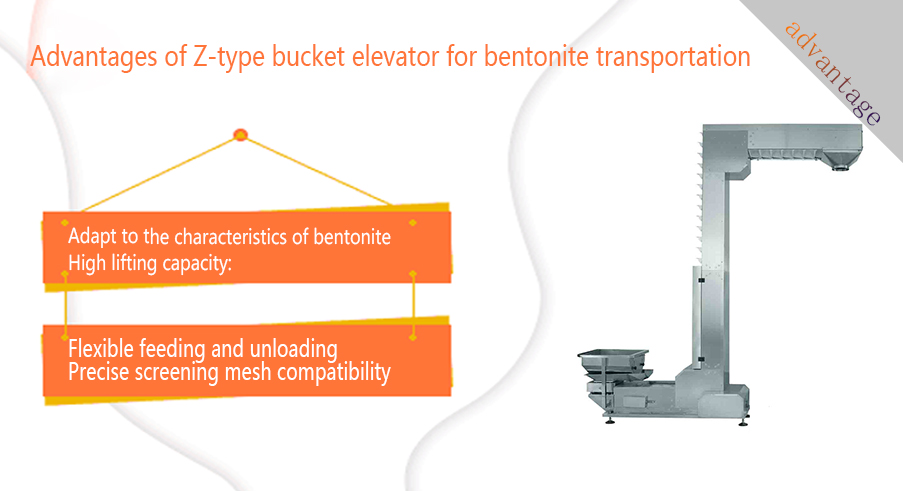

Advantages of Z-type bucket elevator for bentonite transportation

Adapt to the characteristics of bentonite: Considering the viscosity and adsorption of bentonite, the bucket and conveying parts of the elevator are made of special materials, with a smooth surface and not easy to adhere to materials, which effectively avoids the residue and blockage of bentonite during transportation. Plug to ensure smooth transportation.

High lifting capacity: 3-100 cubic meters of bentonite can be lifted per hour, which can meet the needs of production enterprises of different sizes.

Flexible feeding and unloading: single-point or multi-point feeding can be achieved, and single-point or multi-point unloading can be completed through the unloading device. This flexible feeding and unloading method enables it to perfectly cooperate with various production equipment.

Precise screening mesh compatibility: The equipment can seamlessly connect to the vibration screening system, support 20-400 mesh (0.075mm-0.85mm) multi-stage screening requirements, accurately separate bentonite of different particle sizes, and adapt to sub-segments such as activated white clay, drilling mud, and granulated feed. Through frequency conversion control, the conveying speed adjustment of 0.5-2m/s is achieved to match the processing capacity of the screening equipment to avoid blockage or overload.

Recommended mesh size for Z-type bucket elevator for bentonite transportation

|

Application field |

Recommended screening mesh size |

Recommended reason |

|

Foundry sand bentonite |

60 mesh-100 mesh |

Ensure the bonding of the sand, uniform particle distribution, suitable for modeling requirements |

|

Drilling mud bentonite |

150 mesh-200 mesh |

Requires high fineness, improves mud stability and suspension performance |

|

Cat litter bentonite (spherical/granular) |

3-5mm particles (about 4-10 mesh) |

High particle integrity requirements to prevent breakage, the elevator needs to be gently transported |

|

Bentonite for waterproof blanket (GCL) |

about 100 mesh |

easy to lay evenly and improve the compactness of waterproof layer |

|

Fine chemical bentonite |

above 200 mesh |

used for catalyst carrier and adsorbent, with extremely high fineness requirements |

|

Bentonite for feed and agriculture |

100 mesh |

easy to mix evenly, improve adsorption effect and dispersibility |

Application of Z-type bucket elevator for bentonite transportation

Drilling mud preparation: Bentonite is required to make drilling mud in oil and natural gas drilling. The Z-type elevator is used to accurately transport high-fineness bentonite (above 200 mesh) to the mud preparation tank to avoid dust pollution.

Environmental protection industry: During the transportation of bentonite cat litter particles, the particles must be kept intact and free of debris. The Z-type bucket elevator is gently transported to protect the appearance of the finished product. It is suitable for feeding materials with a finished product particle size range of 3-5mm.

Building materials industry: When producing waterproof materials and bentonite waterproof blankets (GCL), the bentonite transportation Z-type elevator is used to transport bentonite powder to the distribution equipment or mixer, requiring no agglomeration or wall sticking during the lifting process.

Chemical industry: When bentonite is used as an adsorbent or catalyst carrier, the material flow needs to be precisely controlled. The Z-type bucket elevator can be linked with the metering system to achieve quantitative transportation.

Feed/agricultural application: Bentonite is added to some feeds and soil conditioners. The Z-type bucket elevator is used to transport pre-treated bentonite powder or particles to ensure uniform composition and pollution-free lifting process.

Foundry industry: Bentonite is used as a binder for foundry sand. It needs to be screened to about 100 mesh and then sent to the sand mixing equipment through the bentonite transport Z-type bucket elevator to ensure uniform particles and no secondary crushing.

In view of the characteristics of bentonite such as easy moisture absorption and fine dust, the Z-type bucket elevator has become one of the indispensable core equipment in the bentonite processing production line with its advantages of good sealing, stable transportation and convenient maintenance. It has improved production efficiency and reduced material loss in many specific scenarios. Whether it is 80 mesh coarse particles or 325 mesh ultra-fine powder, it can provide efficient and stable transportation solutions.