Z-type bucket elevator for mining

Monday June-16 2025 15:25:02

Z-type bucket elevator for mining is a vertical and horizontal combined conveying equipment designed for mining material transportation. It has a "Z"-shaped structure and is suitable for the efficient lifting of powdery or small block materials such as ore, mineral powder, and coal. The bucket is pulled by a chain or belt for continuous conveying, achieving low-speed and stable operation, reducing the material breakage rate, and is particularly suitable for mining production lines with high requirements for conveying efficiency and material integrity.

Its conveying path can flexibly set horizontal feeding, vertical lifting and horizontal discharging, and the lifting height can generally reach 5 to 25 meters. It is a reliable solution for vertical transportation of mining materials.

What are the applicable materials for the Z-type bucket elevator for mining?

The Z-type bucket elevator for mining is suitable for the vertical transportation of a variety of materials, especially those commonly used in mining, coal, metallurgy, building materials and other industries.

Ore and minerals: including iron ore, copper ore, bauxite, etc.

Coal: used for material lifting during coal mining and processing.

Cement and limestone: suitable for the lifting of raw materials in the cement production process.

Aggregates: such as sand, gravel and other building materials.

Metallurgical powder: such as iron powder, copper powder and other metal powders.

Chemical raw materials: certain chemical products with temperature resistance requirements can also be transported using high temperature resistant bucket elevators.

Which is better, a centrifugal bucket elevator or a continuous bucket elevator?

|

Comparison project |

Centrifugal bucket elevator |

Continuous bucket elevator |

|

Picture |

|

|

|

Discharging method |

Centrifugal discharging: The bucket is thrown out by centrifugal force after running to the top |

Gravity discharging: The bucket slowly turns over and discharges by its own weight |

|

Bucket arrangement spacing |

The bucket spacing is large and sparsely distributed |

The bucket spacing is small and almost continuously arranged |

|

Lifting speed |

High speed (tape type: ≥1.0m/s, chain type: 0.5~0.75m/s) |

Low speed (generally ≤0.5m/s) |

|

Applicable material type |

Dry, fluid, non-sticky powdery and granular materials |

Highly sticky, easily broken or high in water content Materials |

|

Material breakage rate |

relatively high |

low breakage rate, suitable for fragile materials |

|

Bucket structure |

mostly shallow buckets, such as Q-type buckets |

mostly deep buckets, such as Z-type buckets and H-type buckets |

|

Typical structural forms |

TD-type and TH-type bucket elevators are often used |

NE-type and Z-type bucket elevators are often used |

|

Applicable occasions |

rapid lifting of conventional powdery and granular materials such as cement, sand, and grains |

gentle conveying of materials such as clay, coal, fertilizers, and food |

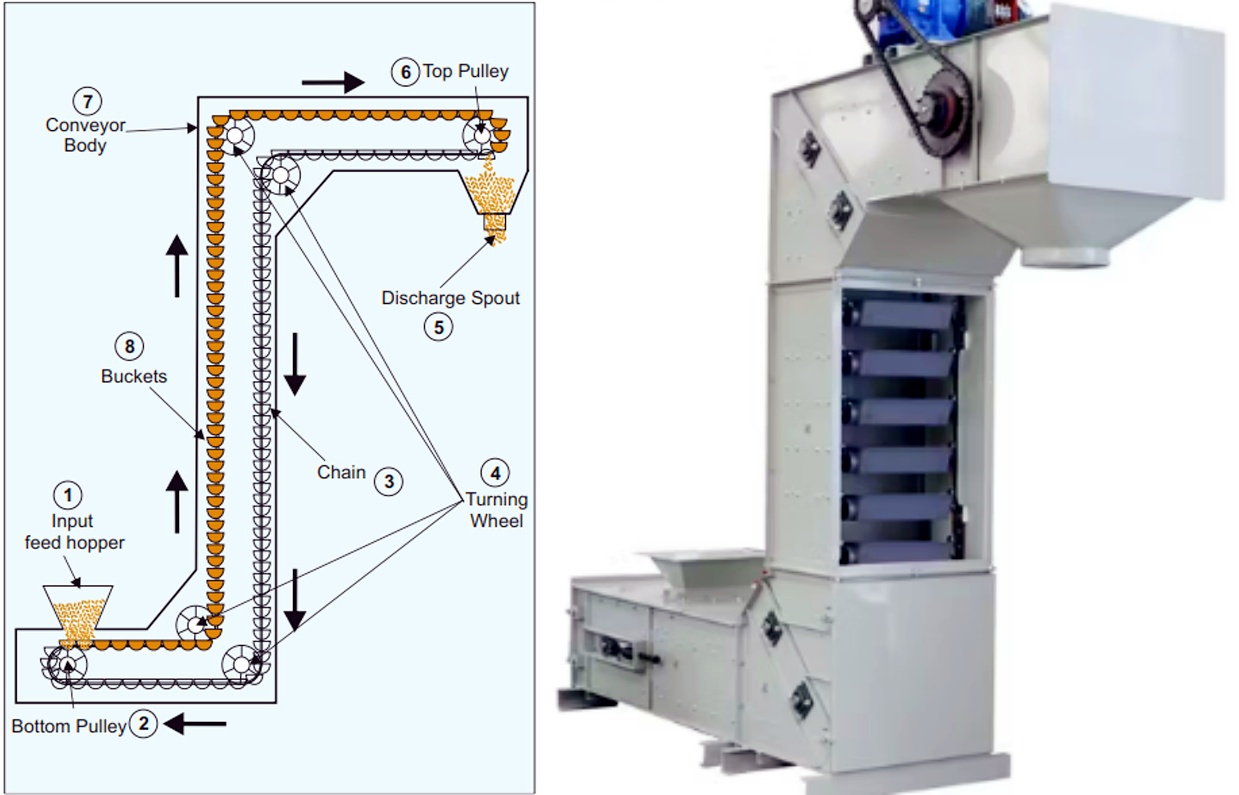

How does the mining Z-type bucket elevator work

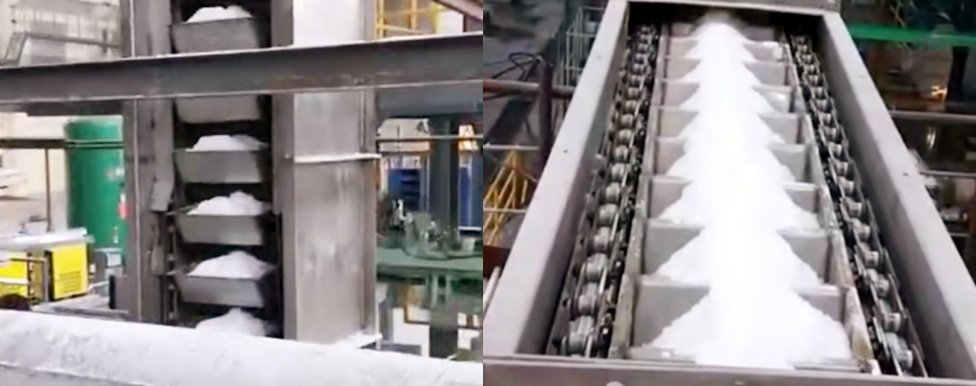

The mining Z-type bucket elevator uses chains or belts as traction components, and the bucket is fixed on the traction component for cyclic movement. The material enters from the feed port of the bottom horizontal section, and the bucket scoops or loads the material through the guide plate during operation. As the traction component moves, the bucket rises along the "Z"-shaped track. When passing through the inclined section, the material is close to the bucket wall due to centrifugal force and gravity to prevent spilling. After reaching the top horizontal section, the bucket unloads the material through centrifugal force or gravity, and the material is thrown into the discharge port or slides into the target container. The empty bucket returns to the bottom along the other side of the track, forming a closed loop.

What can the Z-type bucket elevator be used for in the mining field?

The Z-type bucket elevator plays a key role in material transportation in the mining field. Its unique Z-shaped layout enables it to efficiently lift and transfer various mineral materials in the horizontal and vertical directions.

Material transportation in the ore dressing plant, such as lifting the crushed ore from the crushing workshop to the ball mill or classifier for further processing; in the coal washing plant, it is used to lift the raw coal from the ground to the washing equipment, or to transport the washed clean coal and gangue to the yard or processing area respectively; in the tailings pond treatment, it can be used to lift the solid part of the tailings slurry after dehydration to the designated area; in addition, it is also often used for the transportation of underground materials in mines, such as lifting the coal or ore produced by excavation or mining from the working face to the main conveyor belt, or transporting the filling material from the ground or a transfer station to the goaf for filling, so as to realize the continuous and closed transportation of materials.

What is the typical capacity of a Z-type bucket elevator in a mining operation?

The typical capacity of a Z-type bucket elevator in a mining operation may vary depending on the specific design and application, but the general range is:

Small capacity: 5 to 30 tons per hour (tph) for lighter materials or smaller operations.

Medium capacity: 30 to 100 tph for standard mining applications, suitable for most mineral processing.

High capacity: 100 to 300 tph or more for large operations, especially in mineral processing and bulk material handling. These capacities may be affected by factors such as bucket size, speed, and specific materials being transported.

In summary, the Z-type bucket elevator plays a vital role in the mining field, especially in situations where materials need to be transported vertically or at a large angle in a limited space. Through its ingenious "Z"-shaped layout and continuous cycle working mode, it achieves efficient, environmentally friendly and reliable mineral material lifting, playing an important role in mine production.