Z-type industrial bucket elevator for powdered sugar

Friday May-30 2025 17:22:38

What is a Z-type industrial bucket elevator for powdered sugar?

Sugar powder has the characteristics of fine particles, poor fluidity and easy moisture absorption and agglomeration, which makes it prone to blockage and residue during conveying. The Z-type industrial bucket elevator adopts a unique Z-shaped structure, which can realize combined conveying in vertical and horizontal directions, effectively saving space and improving conveying flexibility.

The elevator hopper loads and unloads sugar powder in a gentle manner, which helps to maintain the integrity of the material and reduce the breakage rate. In addition, according to the food grade requirements of sugar powder, the elevator often uses materials such as stainless steel to ensure the sanitation and safety of the conveying process.

Applicable materials

The Z-type industrial bucket elevator for powdered sugar is suitable for a variety of materials with similar characteristics to powdered sugar due to its good structural sealing, stable conveying, and small damage to materials. It is especially suitable for industries with high requirements for cleanliness and dust resistance.

Powder materials (easy to raise dust, general fluidity): white granulated sugar, glucose powder/maltodextrin, milk powder, protein powder, starch (corn starch, cassava starch), cocoa powder, flour, flavor powder, etc.

Fine particle materials (sensitive to damage, uniform particle size): crystalline sugar/brown sugar particles, monosodium glutamate, chicken essence, small-grain puffed food, etc.

Additive powder or particles (food or chemical industry): food additive powder (such as sweetener, anti-caking agent, etc.), chemical powder (non-corrosive, non-strong irritant)

How does the Z-type industrial bucket elevator for powdered sugar work?

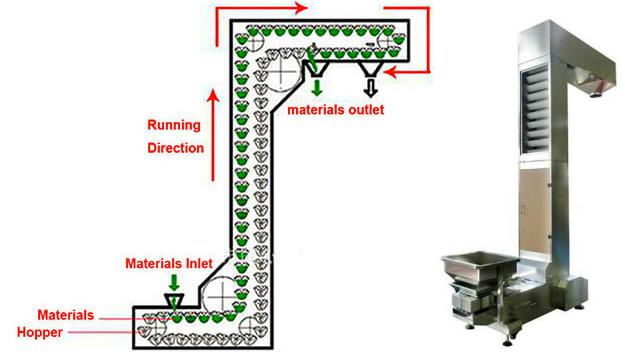

The Z-type bucket elevator consists of an upper drive device, a middle conveying section, a lower feed port, a discharge port, a hopper, a transmission chain or belt, a motor, etc.

①Z-type structure means that the lifting path is in the shape of "Z", the material is fed in horizontally from a lower position, lifted vertically and then discharged horizontally, which is suitable for occasions where workshop space is limited or multiple equipment stations need to be connected.

② Bucket lifting principle: relying on a set of buckets with fixed spacing, driven by chains or belts, scooping up sugar powder from the bottom, lifting it to the top through the middle section, and then unloading it by centrifugation or gravity.

Difference between Z-type industrial bucket elevator for powdered sugar and bucket elevator

|

Comparison items |

Z-type industrial bucket elevator for powdered sugar |

ordinary bucket elevator |

|

Picture |

|

|

|

Applicable materials |

fine powdered materials (such as powdered sugar), easy to agglomerate |

mainly granular or block materials, some can be used for powdered materials |

|

Structural form |

horizontal-vertical-horizontal three-stage "Z"-type structure |

vertical lifting structure |

|

Feeding and discharging methods |

multi-point feeding, fixed-point discharging, flexible layout |

single-point feeding, top discharging |

|

Sealing performance |

good sealing, effective control of dust leakage |

general sealing, powder transportation is prone to dust |

|

Material selection |

mostly stainless steel |

optional carbon steel or stainless steel, depending on the purpose |

|

Typical applications |

food processing (powdered sugar, milk powder, etc.) powder transportation |

conventional material lifting such as building materials, chemicals, grains, etc. |

What can the Z-type industrial bucket elevator for powdered sugar be used for?

Z-type industrial bucket elevator for powdered sugar is widely used in food processing, pharmaceutical and chemical industries, mainly used for efficient and hygienic transportation of powdered sugar. In the field of food processing, powdered sugar is often used in baking, candy manufacturing and beverage production. For example, when making cakes, biscuits and chocolates, the elevator can transport powdered sugar from the storage silo to the mixing equipment to ensure uniform distribution. In the pharmaceutical industry, the high purity and fineness of powdered sugar are crucial to the quality of medicines. The elevator can safely transport it to various production links without destroying the material properties. In the chemical industry, powdered sugar is also often used in the production of spices and condiments as an additive. .

What is the capacity of the Z-type industrial bucket elevator for powdered sugar?

The capacity of the Z-type industrial bucket elevator for powdered sugar usually depends on the specific design and manufacturing standards. Generally speaking, its capacity ranges from about 0.1 tons/hour to 20 cubic meters/hour, depending on the equipment model, hopper size and operating parameters.

|

Bucket specifications |

single bucket volume (L) |

conveying speed (bucket/minute) |

theoretical conveying capacity (m³/h) |

applicable instructions |

|

Small |

1~3 L |

10~30 |

0.5~5 m³/h |

suitable for small batch and intermittent feeding production lines |

|

Medium |

4~8 L |

15~35 |

2~10 m³/h |

commonly used for sugar powder transportation in general food factories |

|

Large |

10~15 L |

20~40 |

8~20 m³/h |

suitable for production lines with large demand for sugar powder |

It is recommended to select a matching model based on the daily processing capacity of the production line (e.g. 5 tons of sugar powder needs to be transported per hour, calculated based on the bulk density of sugar powder of 0.8t/m³, a model of more than 6 cubic meters/hour should be selected) and the process layout (such as multi-point unloading requirements), and give priority to testing the compatibility of materials and equipment. However, different models and configurations may vary, and the specific capacity needs to refer to the technical parameters provided by the manufacturer. If more detailed specifications are required, it is recommended to check the relevant product manual or contact the supplier.

Z-type industrial bucket elevator for powdered sugar is a bucket elevator optimized for the particularity of powdered sugar. It pays more attention to the stability, sealing and hygiene of the conveying process, as well as the adaptability of the overall layout of the production line. It can convey powdered sugar to the required height or equipment smoothly, efficiently and hygienically, and is an ideal conveying solution in the production and packaging of powdered sugar.