Truck Loading Cement particle Suction Machine

Friday April-25 2025 17:35:12

Truck loading cement particle suction machine is a specialized equipment used for efficient unloading of bulk cement particles or other powdery and granular materials, commonly found in construction sites, cement plants, and logistics transfer scenarios. Its core function is to quickly suction cement particles from the truck cargo box to the storage bin or mixing plant through pneumatic conveying technology, while reducing dust leakage.

How does the truck loading cement particle suction machine work?

The main working principle of the truck loading cement particle suction machine is to use pneumatic conveying technology:

① Generate airflow: Generate airflow with a certain pressure and flow rate through a fan or air compressor.

② Inhalation of cement: The airflow enters the cement storage facility through the suction port or nozzle, suspending cement particles in the airflow.

③ Transporting cement: The airflow suspended with cement particles is transported through pipelines to the top inlet of truck trucks.

④ Separate unloading: A separation device (such as a cyclone separator or a bag filter) is usually installed at the top of a truck tank truck to separate cement particles from the airflow and drop them into the tank truck by gravity. The separated clean air is discharged into the atmosphere.

Structure of Truck Loading Cement Particle Suction Machine

Truck loading cement particle suction machine is usually a mobile pneumatic suction device used to suction and transport particle from the ground, storage bin, container bag and other locations into the truck. It is commonly used in particle processing plants, docks and other scenarios. The main structure of this device is:

Conveyor hose or pipeline system: usually flexible hose (easy to move) or steel wire skeleton rubber pipe.

Wear resistant pipe: The material of the spiral pipe is PVC resin, and PVC resin spiral pipe is a very good wear-resistant pipe, which will extend the service life of the cement particle suction machine.

Supporting and moving mechanisms: legs, moving wheels, traction devices.

Control system: electrical control box and operating handle or remote control device.

Drive device: motor, pulley, transmission belt, and safety cover.

Feeding device and discharging device.

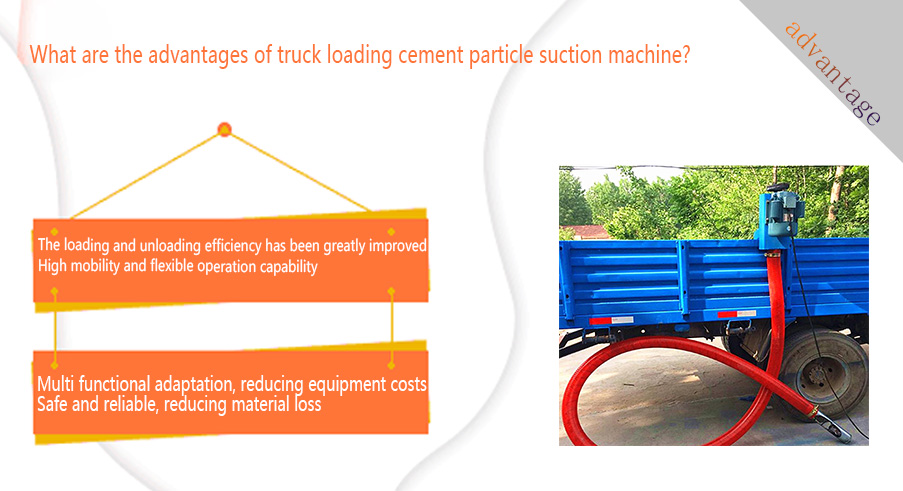

What are the advantages of truck loading cement particle suction machine?

1. The loading and unloading efficiency has been greatly improved: the single machine conveying capacity can reach 30-150 tons/hour (such as DN200 pipeline combined with high-pressure fan), which is more than 10 times the efficiency of manual loading and unloading. The automation control system achieves seamless integration of "suction separation discharge" without the need for manual intervention. Standardized interfaces are compatible with various truck tank ports, and loading and unloading preparations can be completed within 5 minutes.

2. High mobility and flexible operation capability: The equipment is directly installed on the truck chassis, without the need for additional fixed sites or infrastructure, and can be quickly moved with the truck to different construction sites, warehouses, or production lines. Suitable for remote areas, narrow spaces, or multi site operations (such as concrete mixing plants, construction sites, etc.).

3. Multi functional adaptation, reducing equipment costs: In addition to cement, it can also transport granular/powdery materials such as fly ash, mineral powder, sand, etc., adapting to various working conditions and improving equipment utilization. Traditional loading and unloading may require the cooperation of other equipment, while suction machines can independently complete the entire process of "suction transportation unloading".

4. Safe and reliable, reducing material loss: The pneumatic conveying process is gentle, avoiding cement particles from being crushed or graded due to mechanical collisions, and maintaining stable material quality. Closed pipelines and sealed interfaces can prevent cement from getting damp, contaminated, or leaking, especially suitable for operations in harsh weather conditions such as rainy days, reducing material waste.

Application of Truck Loading Cement Particle Suction Machine

Bulk cement shipping station in cement plant

Scenario description: After cement production is completed, a large amount of bulk cement needs to be quickly loading into cement tankers that come to pick it up from storage bins (such as vertical silos and horizontal silos) inside the cement plant.

Application: The truck loading cement particle suction machine can be directly driven to the shipping station of the cement plant, and connected to the discharge port of the cement plant's storage bin through its suction system. After starting, the fan generates airflow, which sucks out cement particles from the silo, passes through the conveying pipeline and separator, and finally unloads them into the tank of the cement tanker.

Large transit warehouses or bulk cement distribution centers

Scenario description: Bulk cement transfer warehouses will be established near some large building materials markets, ports, or railway freight stations.

Application: The cement particle suction machine loading on trucks can be used to load cement from the transfer warehouse into trucks that come to pick up the goods. Strong flexibility, able to adapt to different locations of silos and different types of transportation vehicles. The efficient loading capacity ensures the rapid turnover of the transit warehouse.

Concrete mixing plant

Scenario description: In order to reduce costs and improve efficiency, mixing plants usually directly purchase bulk cement.

Application: Many mixing plants will build fixed pneumatic conveying systems to unload bulk cement from tank trucks into silos. However, in some cases, such as when the mixing plant needs to retrieve materials from temporary storage points or distant silos, the mobile suction machine loading on trucks can play a role in transporting cement particles to the storage bin of the mixing plant.

Cement product factory

Scenario description: Prefabricated component factories, cement pipe factories, etc. also extensively use cement as raw material.

Application: The cement granule suction machine loading on trucks can be used to unload bulk cement transported from tank trucks into the storage bin of the factory. In some factory areas, if it is necessary to transfer cement from one silo to another, mobile suction machines may also be used.

Emergency or temporary cement transportation scenarios

Scenario description: In some emergency situations, such as fixed conveying system failures or the need to temporarily build cement conveying channels.

Application: The mobile suction machine loading on trucks can serve as a quick deployment solution to transport cement from temporary storage points to where it is needed.

Suggestions for the selection of truck loading cement particle suction machine

1. Thoroughly evaluate your loading requirements and goals: loading materials, loading speed requirements, conveying distance and height, bin type and interface, truck type and interface, operating environment, mobility requirements, etc.

2. Determine the appropriate conveying method based on demand: negative pressure conveying (suction conveying), positive pressure conveying (pressure conveying)

3. Select appropriate fans, suction systems, conveying pipelines, separators, and unloading systems based on the conveying method and loading requirements.

4. Consider whether a dust removal system and automation control system are needed.

5. Choose the appropriate chassis and structure based on mobility requirements.

6. Taking into account the price, performance, and maintenance costs of the equipment, choose the most cost-effective solution.

Truck loading cement particle suction machine achieves rapid loading of bulk cement through efficient, energy-saving, and automated methods, significantly reducing labor intensity, environmental pollution, and material loss, and improving loading and logistics efficiency. It is an important equipment for modern bulk cement logistics.